Delamination and uncut fibers are just a few of the special challenges presented by routing composite materials. For every application, there’s a RobbJack PCD tool to get the job done right and done fast.

RobbJack supplies PCD-tipped drills to our clients all over the country and in several industries. We’ve worked with applications in the aerospace, automotive, medical, and manufacturing industries, and we have the experience necessary to recommend the right drill for the right job. If you have any questions about our polycrystalline diamond tools, don’t hesitate to contact us; one of our expert support team members will gladly give you assistance.

This tool is designed to rout profiles and pockets in thin carbon fiber panels for high-tech backpacks, delivering better finishes with minimal fraying and fiber pull-out. Its precise profile design and excellent finish save hours of hand sanding and finishing, while offering exceptional durability—lasting up to ten times longer than carbide or diamond-coated alternatives. Standard sizes range from 0.125-inch to 1.00-inch in diameter, with custom sizes available upon request.

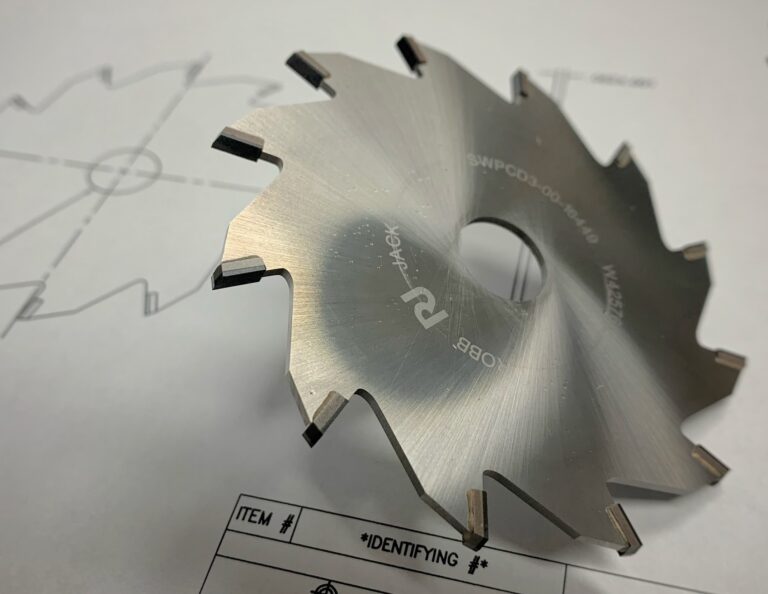

Featuring ultra-shear geometry for minimal burr in composites, this tool ensures clean cuts with minimal delamination or uncut fibers. PCD tips can be re-tipped and re-lapped at a fraction of the cost of new tools, providing exceptional value and longevity. With superior efficiency, a single pass replaces three passes of a carbide saw when cutting carbon-filled PEEK—offering an impressive 50:1 advantage in tool life.

Featuring PCD-tipped, high-rake geometry, this tool delivers ultra-fast cutting and clean results in composite materials with minimal delamination or uncut fibers. Its exceptional durability allows for re-tipping and re-lapping at a fraction of the cost of new tools, extending its service life. Compared to grit-style hole saws, it can cut cycle time in half, significantly improving efficiency and productivity.

RobbJack is utilizing a new and revolutionary technology in the manufacture of PCD tools. This new technology improves tool quality, PCD adhesion to the tool body, and increases heat resistance during cutting. All of these improvements allow tool performance that was once impossible.