Our applications support specialists have been helping customers achieve target performance, efficiency, and quality for over five decades. Give us a call for help with your challenging machining problem: (800) 527-8883

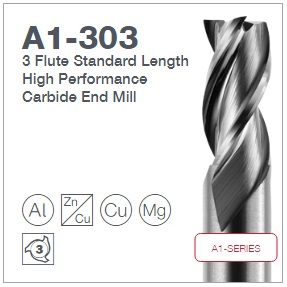

When an automaker switched to aluminum, only RobbJack met the machining requirements where over 20 other toolmakers failed.

In pursuit of performance and fuel efficiency, automakers are increasingly switching from heavy steels to lighter aerospace aluminum for everything from body panels to door frames. An American light duty truck manufacturer recently made this switch. It needed consistent performance within demanding parameters: to cut the cycle times in half by more than doubling the feed rate.

Over 20 toolmakers tried—and failed—on multiple counts:

Then RobbJack took on the challenge.

This powerful tool had all the features needed to deliver the goods, including:

This powerful tool had all the features needed to deliver the goods, including:

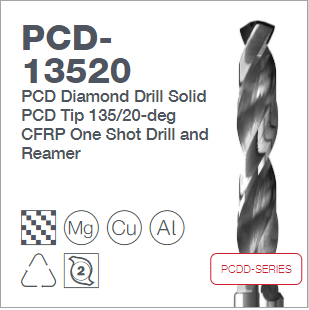

When drilling carbon fiber reinforced polymer (CFRP) wing spars, an aircraft manufacturer struggled with poor quality cuts and expensive scrap until switching to RobbJack’s new Single Shot PCD diamond drill.

Prized for its high rigidity and strength-to-weight ratio, CFRP is notoriously difficult to machine without delamination, uncut fibers and fiber pullout. One manufacturer was going through 25 carbide drills to make one ship set of wing spars, scrapping many very expensive parts along the way. The process was intolerably costly and unstable.

OUR SOLUTION: THE SINGLE SHOT PCD-TIPPED 135°/ 20° 8 FACET TIP, DESIGNED SPECIFICALLY FOR CARBON FIBER COMPOSITES

This powerful, newly developed tool had all the features needed to do the job right, including:

The RobbJack PCD-Tipped 135°/ 20° Single Shot Drill consistently achieved clean, precise cuts. Plus, freed from the hassle and time of replacing worn drills, the manufacturer achieved increased capacity & throughput.

Before: High performance carbide CFRP drill caused poor quality holes marked by delamination, uncut fibers and fiber pullout.

The new carbide material and new coating combination in RobbJack’s DM/MDM Die/Mold Carbide End Mill lasts 450% longer than comparable carbides and coatings designed for hard metal applications—and reduces wear by 909%.

Hard milling applications are becoming more complex with tighter tolerances. Poor tool life requires tool changes in the middle of a job, magnifies difficulty and leads to scrapped parts.

Tests were conducted in D2 58 HRc, pitting comparable carbides and coatings against our new DM/MDM Die/Mold Carbide End Mills. We compared tool life and tool wear.

Typical tools designed for hard metal machining had a wear land or deep notches of .0275”. The new RobbJack DM/MDM series tool outperformed every test tool with a smooth wear land of only .0025”. That’s a whopping 909% less wear.

The RobbJack DM/MDM with revolutionary new carbide and coating lasted so much longer than any other tool we were able to cut molds in difficult material 450% longer—completely eliminating the need to switch tools midway through and hope for the best. The new tools generated less heat, held size, and cut the part within tolerance.

Additional Details

Before: Typical hard metal carbide grade and coatings for molds.

After: New revolutionary carbide grade and coating. “The one to get it done.”

When trimming carbon fiber reinforced polymer (CFRP) aerospace skins, an aircraft manufacturer struggled with poor cycle times, poor tool life, and expensive scrap until switching to RobbJack’s CPCD diamond trimming tools

Prized for its high rigidity and strength-to-weight ratio, CFRP is notoriously difficult to machine without delamination, uncut fibers and fiber pullout. One manufacturer was going through one carbide burr per part. They had to rough the part in two passes and then change the tool to abrasive diamond grinding tool to finish the part. Requiring 3 passes to finish the part.

RobbJack took on the challenge!

CPCD-203 series PCD Trimming tool, Designed specifically for Composites.

The CPCD-203 Series PCD tool roughs and finishes the part in a single pass reducing the cycle time from 20 minutes down to 5 minutes 400% cycle time reduction.

The RobbJack CPCD-203 Series router consistently achieved clean, precise cuts. Plus, freed from the hassle and time of replacing worn tools, the manufacturer achieved increased capacity & throughput.

Total yearly savings $216,000